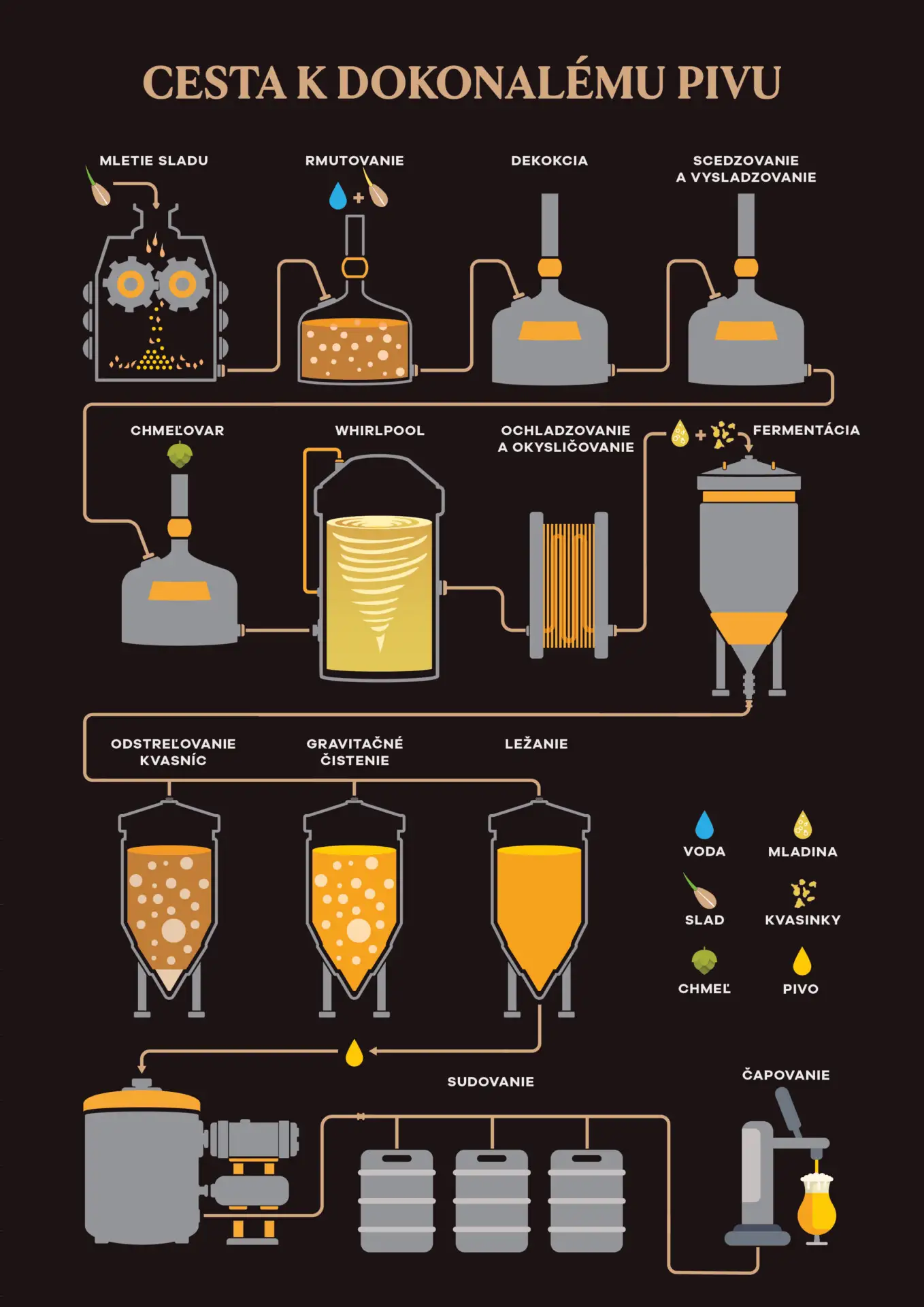

From grain to cup

Milling of malt

The brewing process begins with the milling of the malt. The malt grains are ground to release the necessary substances.

Rumination and decoction: converting sugars with precision

The ground malt is mixed with water at 62 °C to produce mash. In decoction, which is a traditional method typical of Czech brewing, part of the mash is removed, boiled and returned, thereby increasing the temperature by leaps and bounds. This process is important because it activates the enzymes alpha and beta amylases at different temperatures, which convert unprocessable sugars into fermentable ones. The result is wort – the sweet liquid that forms the basis of beer.

Straining and sweetening

During mashing , the wort is separated from the solid parts of the malt (the mash) and flows through a layer of mash that serves as a natural filter. This is followed by a sweetening process in which hot water is added to the malt. This water flushes out the remaining workable sugars, proteins and other substances, thus ensuring maximum utilisation of the raw materials. The result is a clean and rich wort that is ready for the next step – hopping.

Hop grower: adding bitterness and aroma

In hop brewing , hops are added in three stages. We use different types of hops – for bitterness, aroma and flavour. For example, forlagers we use Czech hops and for top-fermented beers such as IPAs and APAs we use aromatic hops from Australia or America. When hops are added to the wort, it becomes wort.

Whirlpool: beer purity under control

Here, the beer is gravity purified – the proteins and tannins react with the hops and settle to the bottom of the vessel. This step is important because it removes impurities and improves the purity of the beer.

Cooling and fermentation

After boiling, the wort is quickly cooled and yeast is added, which converts the sugars into alcohol and carbon dioxide. Fermentation takes place at different temperatures depending on the type of beer – lagers ferment at lower temperatures, top-fermented beers at higher temperatures. At the end, the beer is cooled down sharply to stop the fermentation processes and allow it to mature into its final form.

Maturation: time for perfection

After fermentation, the beer is aged to harmonise the flavours. This process takes 8 weeks for lagers and around 6 weeks for top-fermented beers. In this case, patience produces a tasty beer – we do not shorten the lager period as this would affect the quality and taste. During the lagering period we check and test the beer to see if it meets our expectations and standards.

Ready to enjoy

When the beer is aged in excellent condition, it is filled into kegs and ready for tapping. It can be gently carbonated beforehand to give it the right effervescent texture.